|

Area51 Project Argo - 2020 Update: Adventures & Repairs:

January 18, 2020 Snowmageddon Day 2! Still a state of emergency so on go the Argo tracks! For more details on installing tracks check out my new How To article, Installing Argo Tracks.

Thankfully, since rebuilding the carburetor, Project 6x6 is running fantastic! No more stumbling, I have full power and it idles for days!

The following weekend French and I took the machines down as far as Marine Park where he and his family spend the summers camping in their RV. It was a great shakedown run fairly close to home, and both machines performed great in the deep snow from our mega blizzard.

February 6, 2020 Mark French and I began what would be quite a series of awesome Dual Argo Ice Fishing Adventures as we adapt to the new reality of the Covid-19 Global Pandemic.

February 9, 2020 another day another Argo Ice Fishing adventure, Argo exploring and breaking trails!

Pump side service at Monty's in Whitbourne.

February 23, 2020 Goose Pond Argo Rip.

March 13, 2020 Awesome Argo run in Salmonier, St. John's Rod and Gun Club and Peak Pond.

March 15, 2020 Triple Argo Ice Fishing trip in Salmonier. French and I logged a lot of hours on the machines this winter with many ice fishing trips and exploratory runs looking for even better, more remote ice fishing destinations.

Spring riding got a little tangly on my Mid April Torbay Argo Rip as brooks were opening up and snow got loose and slippery. My plan B ratchet strap worked great to haul the machine backwards and to the right up out of the crevice eroded under the snow.

April 2020. Still in the midst of the Covid-19 pandemic we are all spending the majority of our time safe at home avoiding exposure to this terrible virus that has gripped the entire world. On the bright side it allowed me a lot more free time to get some maintenance completed on Project 6x6 after an busy winter of tracked Argo Adventures with Mark French.

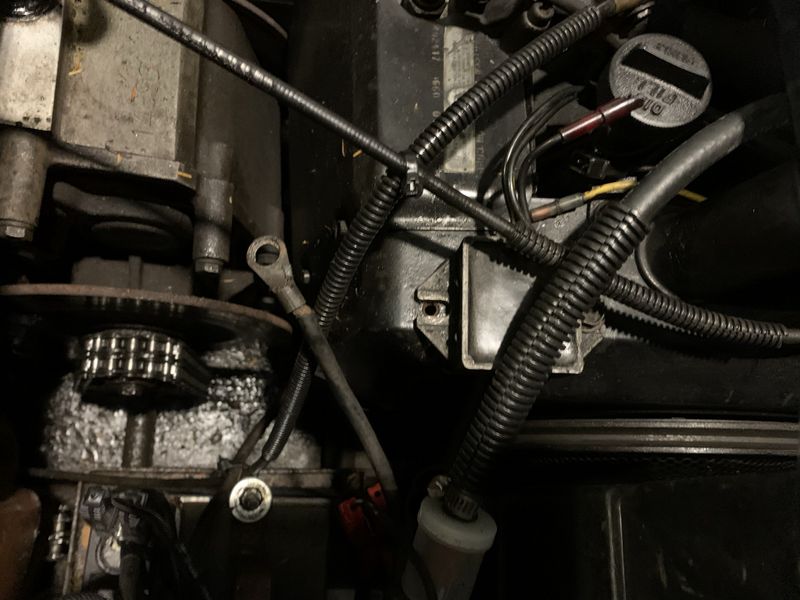

First up was greasing the drive chains which I try to do about every 10 hours as it's cheap, easy insurance against premature wear. I simply jack up one side at a time and spray Castrol chain lube with one hand and turn the track or tire with the other hand.

On my 6x6 I can reach three sets of chains from the engine compartment. Idler chain from transmission to idler shaft, idler shaft to front wheel, and idler shaft to middle wheel. The rear chains are accessed by removing the rear floor pan.

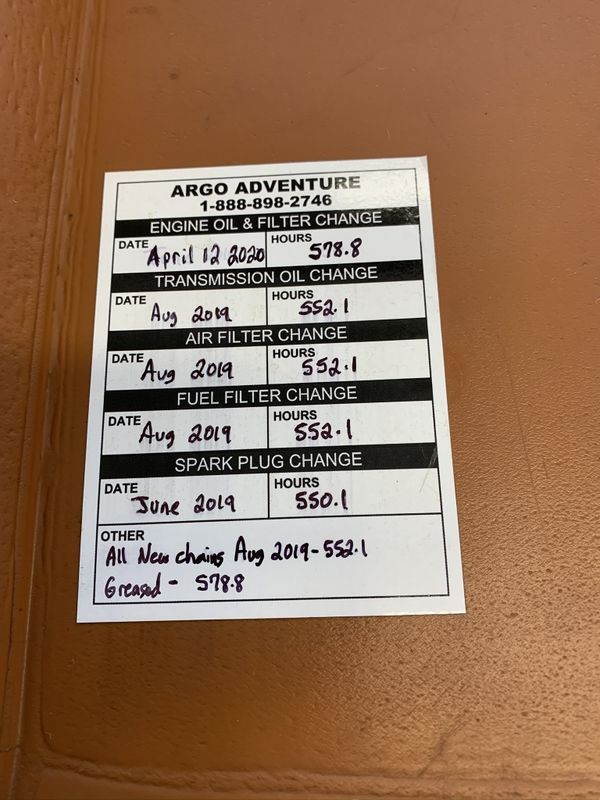

Also completed today was greasing of wheel bearings and an engine oil change. I have put 28 hours on the machine since purchasing it this time last year! Permanent marker on my service decal is cleaned with Brake Parts Cleaner and updated info written in.

Earlier this winter I replaced a lot of snap fasteners on the convertible top using a kit from Canadian Tire which turned out to be of very low quality as most of them broke. Today I replaced those fasteners with quality stainless steel pieces purchased in a kit at Blue Water Marine.

With snow all but melted and temperatures on the rise, it was time to covert the machine from winter back to summer mode.

The tracks are easy to remove by first finding the half segment which had brand new rods, collars & set screws installed earlier this year. Since they were coated in anti-seize they came apart easily. After removing the set screw, a round punch and hammer gets the pin moving.

Tracks are easier to move and store if they are bound tight with ratchet straps.

In May I decided to finally paint my mix of 3 old rims which were still bright orange inside, and the 3 new black wheels Dark Grey to have a matching set.

I still had 3 old tires on 3 old rims, I popped one of the other spares on an old rim Dad had in Bay Roberts so the machine could still be moved around while the rest were being painted.

I cleaned up the rims, removed all loose paint from the old rims and gave them a light sanding before wiping down with brake parts cleaner. The outside of each wheel was panted with dark grey Tremclad brush on enamel paint.

I painted the inside of the 3 old rims with gloss black Tremclad brush on paint to cover up the god awful neon orange.

Drying and curing.

In May the manual windshield wiper I ordered on EBay in January finally arrived! At $6 it was worth the wait.

The Argo windshield had a factory drilled hole for a windshield wiper which had to be enlarged slightly for this aftermarket unit.

The wiper installed with ease and will be a welcome addition this winter!

June 13, 2020. Quick afternoon Argo rip and float/leak test leaving from our house in Torbay. The test went well, I only have one middle axel seal leaking so I'll be making a repair soon so summer Argo trouting can commence!

After a well deserved summer break, in September it was time to get the Argo prepped for Moose Hunting 2020. With no known issues I completed a couple easy tasks such as finally re-installing the OEM engine cooling air intake which directs fresh cold air to the engine cooling fan.

I had to custom cut two 10x32 machine screws to a custom length. They attach the intake to the engine compartment steel frame via two threaded holes, but the wiring harness is directly behind so I trimmed the screws quite short.

Next up was reinstalling my gun boot which will keep my rifle clean and secure while travelling through the country this fall. Last year I installed it sideways in the rear compartment, but on tight trails it got knocked around quite a bit. This installation will still keep it out of the way in a better location for riding tight woods trails.

Moose hunting fall 2020 found dad operating his old machine for the first time in many years as we hunted and successfully filled his tags.

We even managed to find the limits of 6x6 traction!

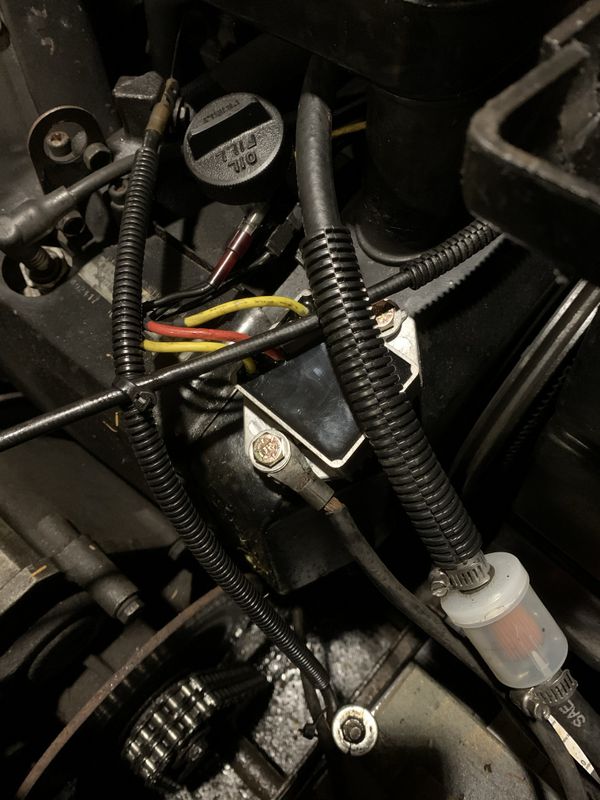

After opening day of Moose hunting I had French drop my machine back to the house for a necessary repair. The 30 year old rubber coupler on the fuel filler neck finally gave out and was leaking fuel as it sloshed around on rough trails.

To replace it I had to drain and drop the tank which is held in place by the same bolts that attach the front seat.

As all this hardware was new it came apart with ease, thankfully I had the foresight to install a weather pack connector on the wire for the fuel gauge which made this job easier.

Full of pin holes, simply due to age!

While the seat and tank were out I decided to replace that centre axel seal and bearings I found to be leaking this past summer. Not a necessary repair for hunting but it was a smart time to complete the job while the tank & seat were out. The opposite centre bearing was replaced during the restoration in 2019.

The previous owner let water accumulate and sit in this machine for quite awhile so the bearings were well seized to the axel shaft. I managed to save some time by not having to uninstall the drive chains, I simply popped out the drive cog shear pins and once the bearings were cut off the axel the it slid out with relative ease. Normally all I would have to do it drive out the 2 sheer pins, loosen the lock collars on the inner & outer bearings, remove the bearing retainer bolts and slide the axel out. Not having to remove the drive chains sure saved a lot of time.

To get the bearing race off the axel I cut it with a Dremel Tool and popped it open with a hammer and punch.

Good as new with new inner and outer bearings, axel seal, fresh grease and a shot of Fluid Film preservative for good measure.

Amazingly our local dealer had the replacement fuel filler rubber coupler in stock. While the filler neck was out of the machine also took the time to replace the 1/8" vent line that runs from up near the fuel filler cap, around the inside of the machine to a through-hull on rear of the machine. This will allow the gas tank to safely vent even with the convertible top installed.

Job done!

Moose Hunting Continued throughout the fall with many great trips to the Southern Shore.

During our hunt a problem developed starting the machine as the battery was going dead. I found the voltage regulator had gone bad and was intermittently not charging/overcharging the electrical system.

Again our new local dealer Melvin's in Tors Cove had a genuine replacement part in stock!

This repair was a breeze, the regulator is right on top of the engine and is held in place with 2 bolts. I did have to cut the connectors off the new unit and solder/heat shrink the connectors from the old one to match the machine.

I also had to install new longer bolts as the new regulator is thicker due to having better cooling fins. This repair completely resolved the issue and the electrical system is now charging properly. The Argo starts well even after sitting in the cold for a couple weeks.

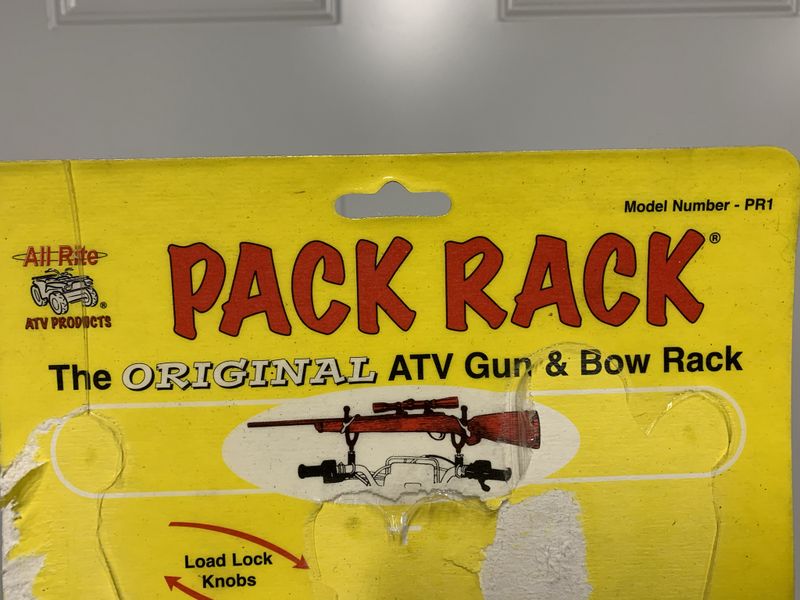

In November I was shopping at Honda One when I came across this awesome old school gun rack which would work perfect on the Argo!

I decided to mount them on the handrail behind the driver seat for easy access while placing the firearm in a safe location from getting knocked about or dirty.

These all metal mounts are coated in thick rubber and have nice rubber straps to secure your firearm.

I made a half dozen trips looking for Moose with Mark and found they work extremely well for both a rifle and shotgun. Argo's are fairly clean and don't spray much mud inside when riding on tires (they are much dirtier if you run tracks in mud).

Our moose hunting season ran longer than usual as we had more licenses to fill this year than most years so we logged quite a few hours on the machines. One of the benefits of an Argo is the ability to take more and larger equipment with you for those amazing backwoods cook-ups! Next Up 2021 Update!

Project Pages: Copyright © 2011 Michael Smith

|