|

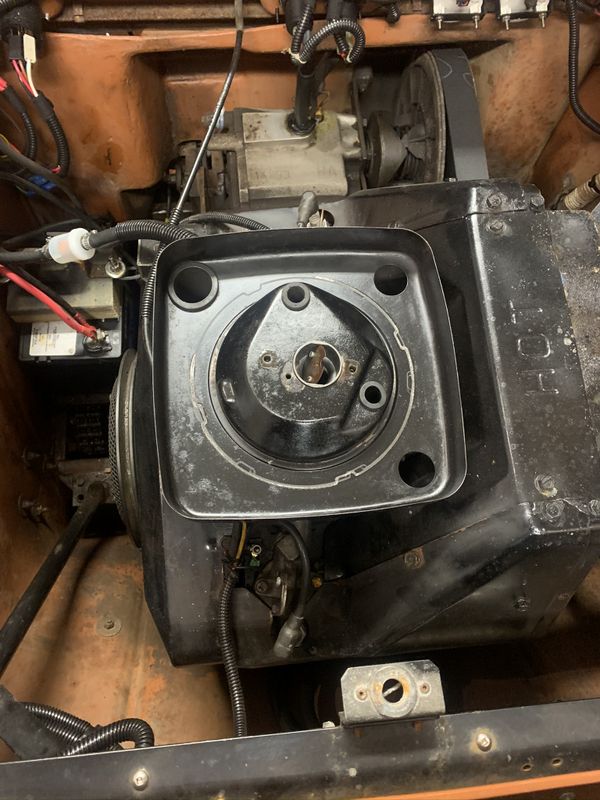

Area51 Project Argo - Carburetor & Fuel Pump Rebuild:

When I purchased this non-running machine in May 2019 one problem it had was the carburetor. It was full of caked in dried up crud. Disassembly and standard aerosol carb cleaner seemed to do the trick and I got the machine running.

However while operating the machine moose hunting last fall I would constantly have to fool with the choke to keep it from stalling, even at wide open throttle, and the only adjustment - idle air mixture - seemed to have little effect. It also didn't seem to be making full power.

I ordered a full carb rebuild kit from Argo Adventure which included all gaskets for the carburetor and gaskets, springs & diaphragms for the built in fuel pump.

Again the carb didn't look all that dirty inside but I knew that a small passage or two had to be blocked off with dried up crud that neither aerosol carb cleaner nor three months of driving with Seafoam in the gas had been able to fix.

Another potential problem was a lot of play and no visible gasket on the throttle shaft which meant it could be pulling un-metered air around the shaft.

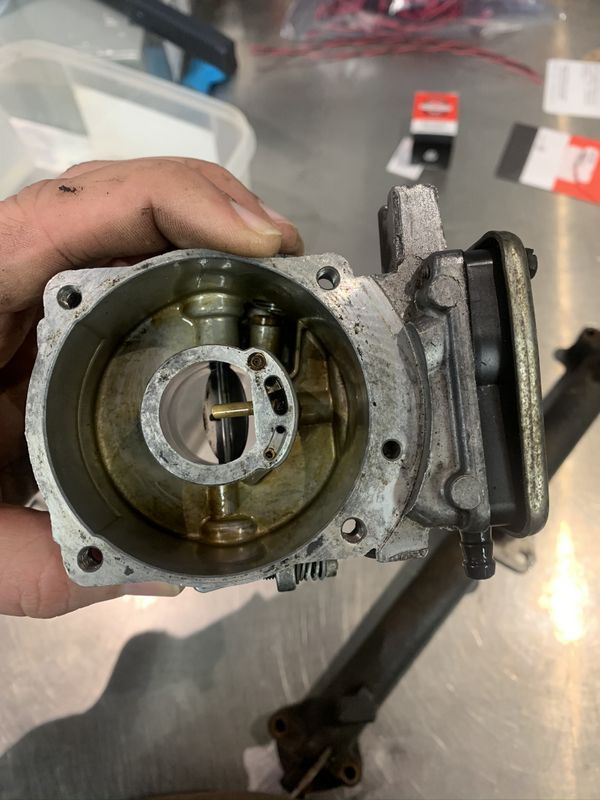

When disassembling a carburetor, especially when taking out the throttle shaft it's a great idea to take a lot of pictures. Also compare your pics to the factory repair manual in case someone else assembled it wrong previously.

The fuel pump was in good shape but the diaphragms were old so a fresh set wouldn't hurt. Also compared to the repair manual one diaphragm and gasket were installed inside out, not sure what difference it made but it wasn't right according to the manual.

Also the small spring in this photo was also not in the right place.

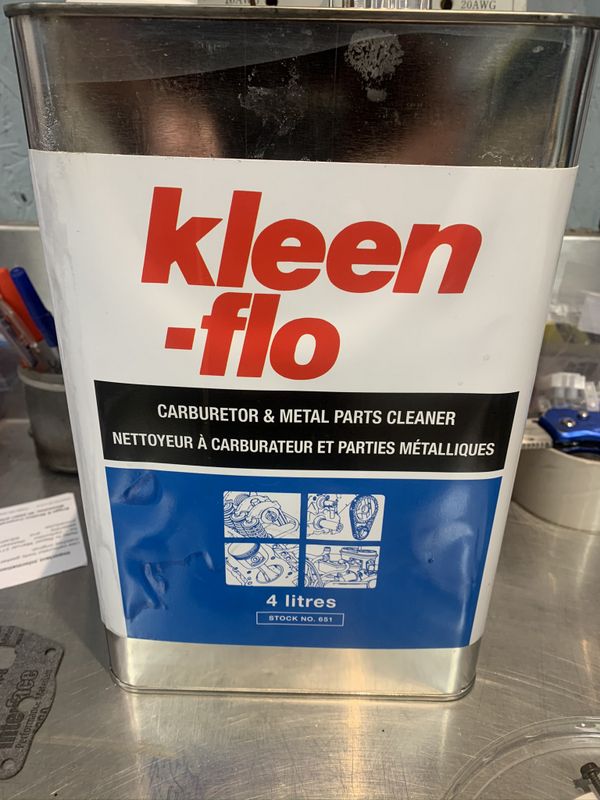

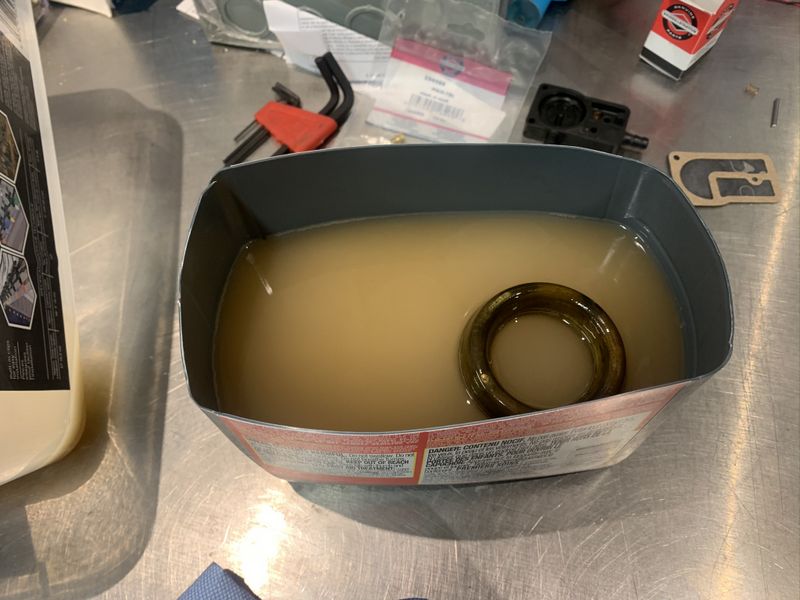

The best part of the cleaning operation was tracking down this awesome product. I've seen dad use it years ago and finally tracked it down at Brown's Auto (not a sponsor). Its Kleen-flo 651 - Carburetor and Metal Parts Cleaner.

Its not cheap at almost $90 for a gallon but this stuff is strong. It will break down anything dirt wise, most rubber, paint and some plastics so you have to be careful what you soak in it and what you soak it in. I cut down an old plastic coolant container and found this product didn't affect it. I laid all metal parts inside, carb body, main jet, brass float, etc, filled the container to cover the parts and let soak for about 8 hours agitating occasionally. This stuff should be used with good ventilation, it's super strong and reeks, but it works.

When clean you neutralize the parts in water, blow dry with compressed air and let sit for a day or so to completely dry. I reassembled the carb with all new gaskets, bushings and springs following the Briggs repair manual. I reinstalled and connected the fuel line and set the air idle mix 1.5 turns out. The machine fired right up after pumping fuel to the bowl and ran excellent even after fully turning off the choke. After a quick test rip I turned the idle air back in to about 1 full turn out as it was a little rich.

The machine is running better than it has in years, I really wish I did this repair earlier in the year before moose hunting as it now has full power and runs with no fooling around at all.

Project Pages: Copyright © 2011 Michael Smith

|