|

Area51 - Mike's Misc Projects 2023:

The new year has arrived, 2 weeks in and we are already into a major mild spell. Warm temperatures and a ton of rain have brought trail conditions right back to spring here on the Avalon. With a potential snow storm coming this weekend, I spent a few nights getting tasks completed in the garage.

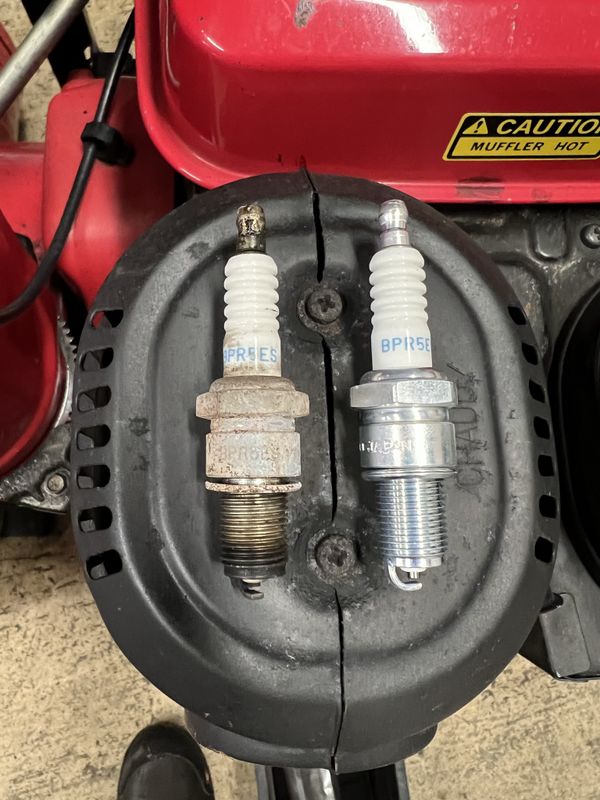

First up was a general maintenance on my 17 year old Honda Snowblower which included draining the carburetor bowl & sediment cup, oil change, new spark plug, greasing the track drive gearbox, general lubrication & inspection.

With temperatures well above freezing it was a great opportunity to get Project Foreman all cleaned up from the last couple rides. It's a lot nicer to store and work on when the bike is free of mud.

Next up was replacing the grips for my Head Demon heated grip kit.

One set screw tightens each grip in place, and now they are removable if I have to replace other handlebar controls. More pics and details can be found on the Project Foreman 2023 Update page.

Next up was a full maintenance on the Argo and track installation. Yes, the Argo does retrieve its own heavy bulky tracks from storage!

While retrieving the tracks, the Argo which hasn't moved since Moose Hunting in September, wasn't running perfectly and wouldn't idle. I popped off the air cleaner then the top of the carburetor finding a little bit of sediment in the bowl.

A fresh quality fuel filter was installed to replace the cheaper one previously installed.

With 10 hours on the clock it was now time to lubricate the drive chains. The Argo manual states a 25 hour interval for this, I go every 10. It's easier to lube the chains than replace them!

I normally change engine oil every 25 hours, but this oil was a year old so I performed this service interval by calendar instead of just following engine run time, cheap insurance for an older engine.

All bearings were greased which is always performed at each drive chain maintenance. On a 6x6 I simply remove the centre wheels on each side, I can reach the rest of the outer grease fittings from here.

Since the machine has to be jacked up to perform chain maintenance it was the perfect time to install the winter tracks. I have my tire diameters measured and placed correctly on the machine so I do not have to move them around each year to install the tracks. For more information on track installation, check out my Argo Track install How To.

Finally, for now, I installed the convertible top roof. I left the side windows off for now, it makes getting stuff off the shelves easier when they are not in the way. More pics and details can be found on the Project 6x6 2023 Update page.

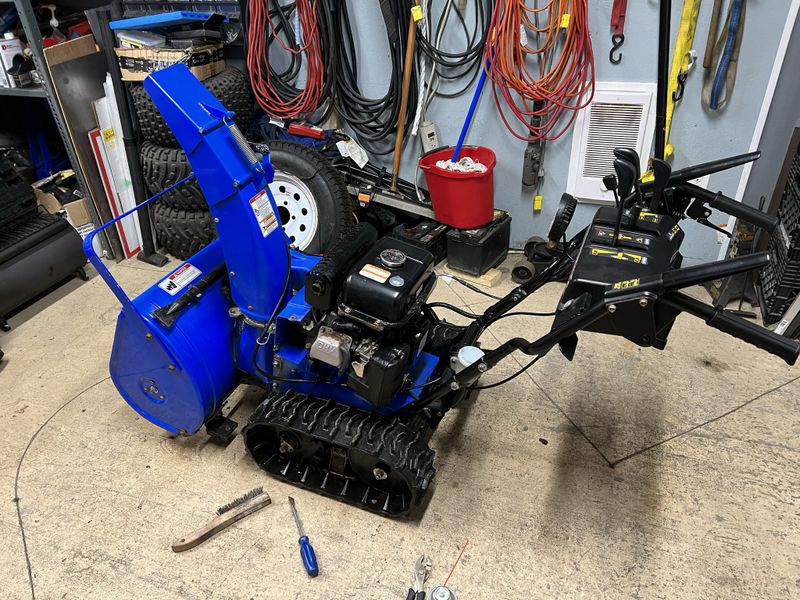

The next job in the garage this week was a maintenance on Andrew French's Yamaha Snowblower, this was my first time working on Andrew's machine.

These machines are similar to the Honda's, the maintenance is the same but they have a different set up for draining the carb and cleaning the sediment cup, but it works equally as well.

Since this is my first time servicing this unit, I removed all the covers and applied a rust preventative coating on the entire frame, fasteners I removed, etc to make working on this machine easier in the future. I also installed a permanent battery tender connector so Andrew can easily plug the machine in between snow storms.

Sediment cup doing its job!

Final step was installing a fresh spark plug for maximum reliability.

The garage was getting quite tight, but I managed to get Andrews machine back to him & my work tools back in the truck right before a 50cm snow storm hit Friday evening.

January 29, 2023 Sunday fun day, today Mark, Stroh and Matthew got together for a BBQ and complete some mods on Mark's enclosed trailer. This unit carries his ATV, Side by Side and Argo, but also doubles as sleeping quarters on Moose Hunting & Salmon Fishing trips. Today the boys plumbed in an external diesel heater which pumps warm air into the trailer while the unit and its exhaust gasses remain safely outside.

It's official, winter has finally returned to the East Coast. After a dismal season last winter, Project REV has been revived from storage and made ready for winter. The machine started with relative ease even with over 2 year old gas! I stored the sled with less than 1/4 tank and topped it up with supreme 91 on the way home.

After our 50cm dump I gave the machine a close inspection and was pleased to find everything in good order. Carb boots intact, Reeds great, nothing missing, no loose bolts, etc. I took the machine on a shakedown run in Torbay and had an awesome and uneventful ride. A full service was performed spring of 2021 prior to storage which included chain case oil & full grease.

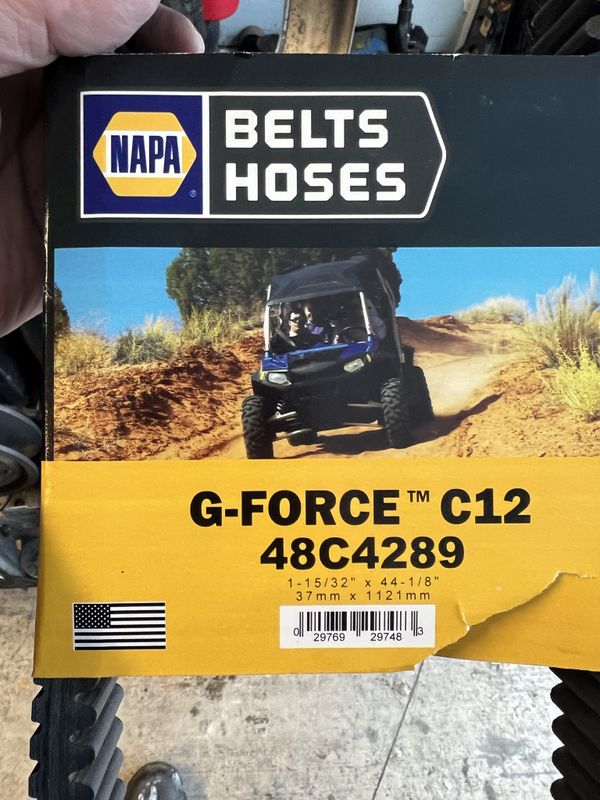

I have a trip planned with Dad coming up in March, the only item I was weary about was the belt. This is the same Gates Extreme belt installed when I rebuilt the sled in 2013! It has a little over 2500km, but it's 10 years old and showing cords.

Since the last Gates belt worked so well, I went with another, now their new Gates G-Force C12 especially designed for high horsepower machines like my 800HO which develop a lot of heat and have forged clutches.

The new belt fit great and now the sled is ready for a great adventure in Indian Bay, NL! (Yes the belt came up just proud of the secondary as its supposed to once I ran the machine.) More pics and details can be found on the Project REV 2023 page.

When I got back from Indian Bay, I stopped down and gave Mark French a hand to finish up a full maintenance on his 2017 Argo Avenger Huntmaster.

The machine logged a lot of hours moose hunting this past fall, it was due for engine oil, filter, transmission oil, full grease and chain lubrication. Mark also flushed the service brake fluid with fresh Dot 5.

My Indian Bay snowmobile trip with Dad went very well. Project REV, my 17 year old beast ran very well, the only hiccup experienced happened on the way in when I fouled a plug after idling the machine for an expended period helping dad with his machine. A brand new set were swapped in and the sled ran great and strong all weekend logging 150km on the clock. Very successful trip that warranted a post run maintenance as found on the Project REV page!

I found the snowblower getting more difficult to steer straight, and pulling up grass while widening the driveway recently. The cause was very worn out side bucket skids!

I threw on a spare set I had in the garage which I will modify later by welding another layer of steel to the bottom for better longevity.

Next up was making another repair to the running boards on my truck, this time to pinch the rotting aluminum over a wider span than the OEM brackets. I drilled holes in these new pieces inline with the mounting bolts for the running boards. The OEM bolts were removed, this piece slid between the board and bracket and bolts reinserted. This pinches the rotting aluminum between the new steel, and steel I placed inside the running board a few years ago for a very sturdy finished product.

With the arrival of spring, it was time to do some cleaning/organizing in the garage in accordance to the change in seasons. I'm leaving the tracks on the Argo for now, but I removed the convertible top for the season. This will make finding stuff on the shelves in the garage much easier.

Next it was time to put Project Rev back in storage for the summer, which will free up a lot of space here at home. It's still freshly serviced so it's ready to ride whenever the snow flies next winter.

On April 6th I had about enough of driving a rotten dirty truck, so step one was a thorough pressure washing.

My Simonize suitcase style pressure washer continues to work great year after year, and takes up very little space inside my already overfilled garage.

The truck was spot treated with degreaser to clean off all the undercoating oil that seeps out protecting panel edges all winter. Then the body panels were washed as usual, including all the door jambs. I didn't hit the underside or chassis hard as I still need my proactive undercoating for a few more weeks before it's thoroughly cleaned and reapplied.

The truck was looking great, so with good weather forecasted for the foreseeable future, I decided to swap over to my summer 20" OEM wheels and BFG KO2's.

These 34" tires suit the truck so much better and actually lift the truck 2" (measured) compared to the much smaller winter tires. Not looking too bad for 12 years old!

Finally (for now) was a quick inspection and rear brake maintenance on Project Foreman, which you can find out more on the Project Foreman 2023 Update page.

In Mid April it was time to replace the rear brakes on our 2020 Murano, the squealers just started making a racket after 40,000km of driving.

The brakes came apart easily, in part because the vehicle is still new, and mostly due to proper brake and wheel hub maintenance. Applying anti-seize since new to the wheel hub not only kept aluminum rims from sticking, but also prevented rust from forming and seizing the rotor in place.

We definitely got our moneys worth out of these pads!

The groove where the stainless pad hardware sits was made surgically clean and a dab of brake lubricant applied to prevent corrosion and rust jacking of the pads. The sliders were thoroughly washed out and fresh high temp lube applied as well.

While the vehicle was in the garage I replaced the air filter as recommended by the dealer at the last oil change. The replacement AC Delco filter seems to be a much better unit than the OEM Nissan one.

At the end of April spring projects continued at Area51 by removing the snow tracks from project 6x6. They won't be used any more until next winter, having them off makes the machine easier to move around the garage and gets the Argo one step closer to summer adventures.

In between trips to Terry's Cabin in Central NL, I picked up and installed a replacement rear brake cable as the old one seized over the winter. The replacement was a genuine Honda part.

It was pretty straight forward to fish it down from the handle bars, along the frame under the gas tank (made accessible by removing the gas tank plastics) then down to the rear axle. The new cable worked great, gave me a working park brake again, and brought Project Foreman back to 100% operation.

One of my last Spring cleaning jobs was swapping over winter for summer rims/tires on the Murano, touching up the undercoating, then washing and putting away the winter rims (which are holding up great!).

More visitors, must be fans of the site!

In June Aaron dropped off his '08 Honda XR650L to mainly get some electrical repairs looked at to make the bike reliable again. The previous owner installed some aftermarket lights and a battery relocation kit and it wasn't done very well. I made some very tidy repairs, built a custom fibreglass instrument cluster housing and performed a general maintenance. Check out the full story on Aaron's bike.

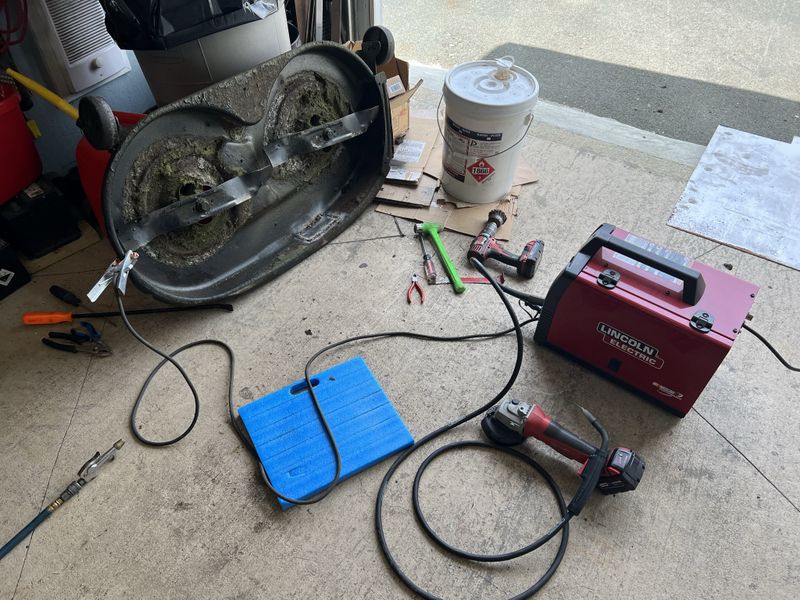

After Aaron's bike was done it was time for some lawn tractor repairs starting with a repair to the mower deck.

A pretty significant hole appeared last summer, a temporary repair didn't last so today I broke out the welder to make a proper repair to the affected area.

A little cleanup and fresh paint will help preserve the deck for the foreseeable future!

An inner tube fixed an annoying leak in one of the rear 1992 vintage tires.

Finally a quick service including oil change and cleaning out the air filter.

In July it was time to once again take on some paint repairs to my trusty 2011 Silverado 2500HD. The goal is to have the truck look respectable from 25' but most important to remove rust and protect the body with fresh paint. I don't have space to haul in the entire truck for a few days so this will be a "get done what can be done in one long day on a day with nice weather" kind of job. I will be using custom mixed spray bombs and leaving good OEM paint as much as I possibly can.

This was my late November 2022 Tremclad pre-winter touch up which although doesn't look great, stopped corrosion in its tracks.

Affected areas were scraped, sanded, hit with a 1.5" 3M pad, sanded to feather the repair before being taped off.

I hit bare metal with etch primer then a couple coats of high build primer. Taping was cut back and the repaired areas sanded and feathered again with the surrounding paint.

Start of the single stage colour coats, this paint mix from Car Quest has clear coat mixed in apparently. I've used it before and it holds up remarkably well.

All in all not too shabby of a repair so far. The inner wheel wells were masked off and repainted black for a nice clean finished product.

Now the paint repairs will be left for 30 days to harden before wet sanding and polishing to really blend the repairs with the surrounding OEM paint.

Pre moose hunting maintenance began with my first at home oil change for the truck. Prices keep going up and up at local shops so I decided to start doing them myself using better quality oil & filters. With the front of the truck raised it was a great opportunity to get the front end greased up as 3/4 ton trucks have serviceable steering and suspension components.

Its been a couple years since I changed the rear diff fluid (also had to replace the rusted & leaking cover at that time) so today I dropped the fluid and refilled with quality Lucas Synthetic 75w90.

Today I came home with another burnt out Low Beam headlight which was only a year old. I stopped over to NL Lightbars and they set me up with Duraseries LED Low Beam and matching Fog lights. These are much brighter than stock, have the same focal length as OEM halogen (as not to blind other drivers) and a much longer lifespan. My High Beams have been upgraded to 55w HID ever since I had the truck and continue to work very well.

Fog lights on this series of GM trucks are most easily reached through the wheel well liner.

With new headlights installed it was time to polish the headlight housings using a Meguiar's headlight restoration kit.

The before and after is a huge improvement. The kit polished out 12 years of pitting and abuse from road salt & sand, the final step of the kit included a UV protecting clear coat.

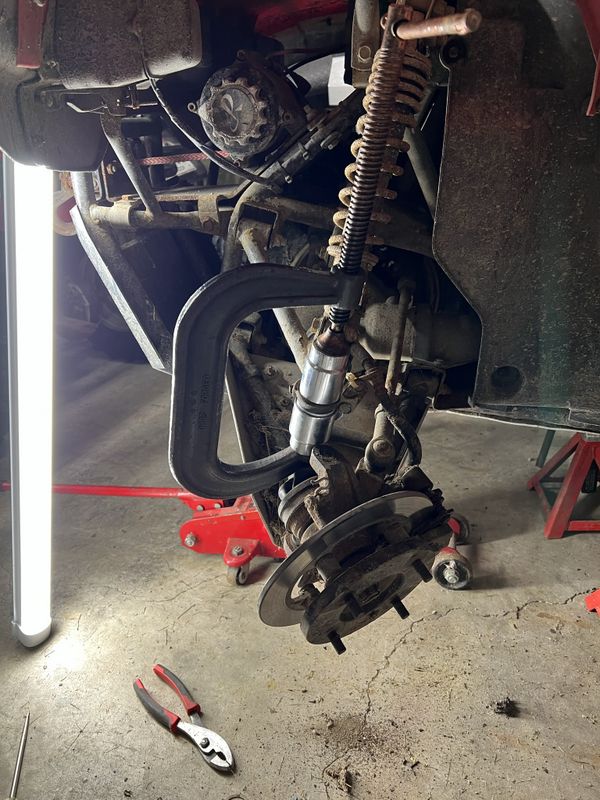

In October Bassan was having some troubles with the brakes on his Honda Foreman 400. We took it apart and found the pads separated from the backing plates. New parts were purchased and installed along with a quick maintenance.

Yup.

Lastly a new left side upper ball joint was installed to replace the sloppy worn out old part.

Now it was finally time to wet sand and polish the truck. This will not only blend the new paint repairs, but also deep clean the OEM paint from road tar & brake dust that washing and clay baring can't remove.

A final layer of protection was added with this fantastic Avalon King Ceramic Coating. The system is very easy to use and the results are long lasting and beautiful.

Quick November work mode pic with my removable ladder rack in place and bed slide turned workbench on this job.

In November I completed an annual maintenance on Doug's Honda 7/24 Snowblower. This year it was a standard oil & sparkplug change, grease and quick painting of the augers which prevents wet snow from sticking to them clogging them up.

With winter right around the corner it was time to get the Murano in winter mode by swapping over to winter rims/tires & touching up the undercoating.

With the Murano complete I undercoated the truck next to upkeep its bi-annual sacrificial layer of protection against harsh winter road salt & sand.

It was a little later before I swapped the truck over to winter tires and rims mostly because I needed new tires. I also wanted to upgrade from my tiny 265/70/17's which are 4" shorter than my summer BFG All Terrains.

This year I picked up a set of used Duratracks in 285/70/17 which are much bigger than my old winter tires, and only about 1" shorter than my summer tires. Picking up a used set let me try the size this winter to confirm fitment before investing in an expensive set of brand new winter tires.

The new tires look so much better on the truck especially with black rims and chrome centres. This will definitely be the size I stick with in the future for winter tires!

Lastly for 2023, in December I popped down to Mark French's where he and Stroh were having a Honda Snowblower service night in preparation for winter. It was a great evening hanging out telling stories which is what Shed-Headz Outdoors is all about!

Cheers, MIKE Copyright © 2025 Michael Smith |