|

Area51 Project - French's Argo Avenger 2020 Update:

In November 2019 our trusty long time local Argo dealer unfortunately closed up shop after providing decades of service to local Argo owners. A new company took over the product line, but not the old mechanics. With that in mind, and my recent experience rebuilding my '89 Argo 6x6 French decided that we would look after service on his machine ourselves.

The old dealer provided top notch service in their shop completing work properly with no worries of skipped steps. With no experienced Argo mechanics at the new dealership French and I took on our first project on his machine - installing winter tracks. We downloaded a copy of the Argo accessory installation guide which is important as there are a lot of critical steps to perform this correctly so you don't break axels and chains. Check out my How To (read: How we did it) on Argo Track installation.

Needless to say, it went well and we logged a whole bunch of hours on both our machines on double and even triple Argo winter adventures. It was a hell of a winter with lots of snow, ice fishing, riding and exploring.

In May it was time to summerize the Argo which has been working flawlessly since purchasing it new in the fall of 2016. This included removing the tracks & convertible soft top, rearranging the wheels, and doing a full service.

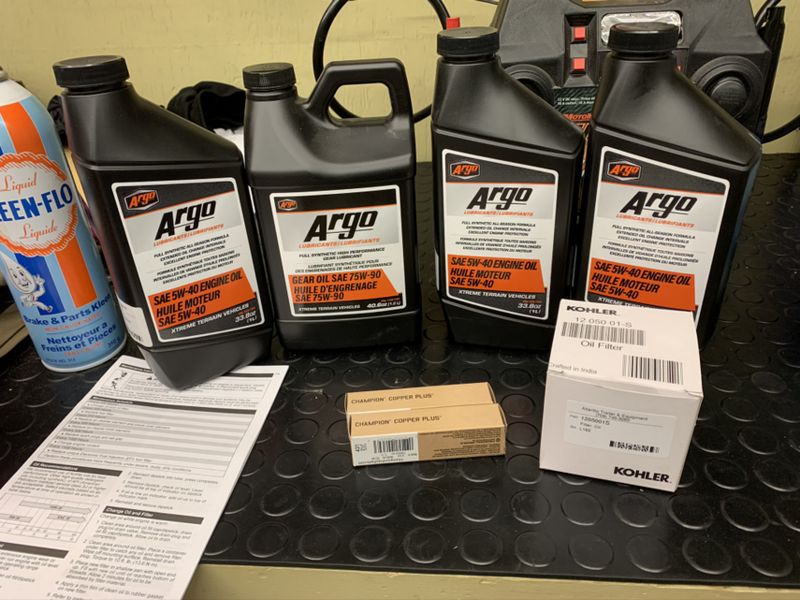

We would be replacing the engine & transmission oils, oil filter, installing new spark plugs, greasing all bearings and inspecting the frame, chains, tensioners, drive belt, brakes etc.

To drain the engine and transmission oil on this machine you need a fluid extractor. Don French had this manual hand pump extractor already in stock and it worked perfectly to remove fluids with ease. While the unit was working away we removed the firewall and changed the oil filter and both spark plugs.

Engine oil replacement was a straight forward affair using one funnel, for the transmission we had to get a little creative using a couple funnels to prevent a mess.

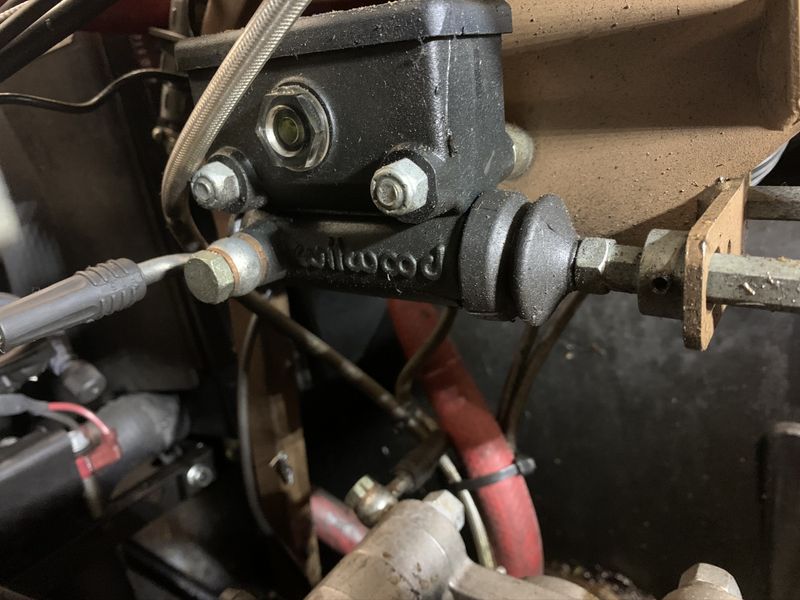

The Admiral Transmission has four brake callipers, two for steering and two for service brakes.

Vented brake discs help keep them cool and free from brake fade.

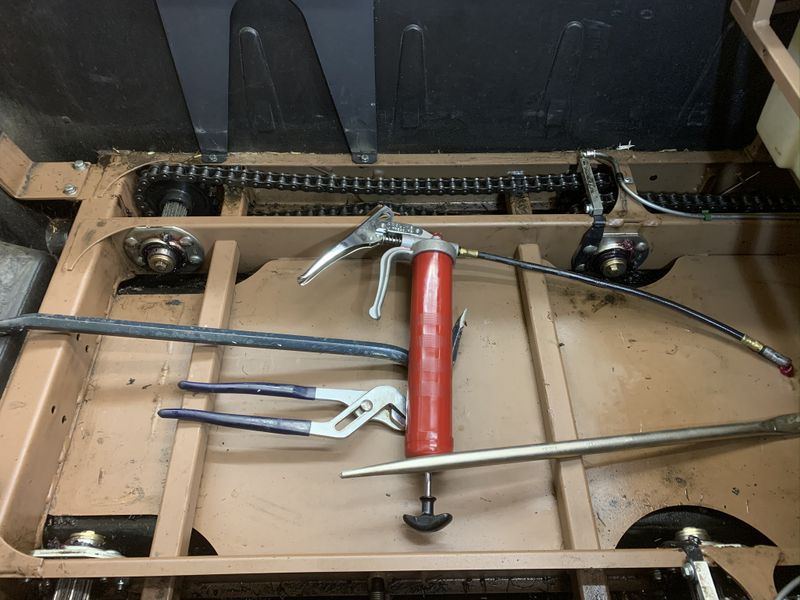

We found one rear automatic chain tensioner had jumped to one of the higher settings which was putting a lot of strain on the left rear chain. It was probably caused by hitting a bump with the machine crossed up in a ditch flexing the frame this past winter. It was a quick fix to set it correctly.

All bearings in the machine have grease fittings. The front ones are a little bit of a PITA to get at, but its easier to grease them than to replace them! Lucas Red n Tacky is French's grease of choice as it's what the dealer used on previous services.

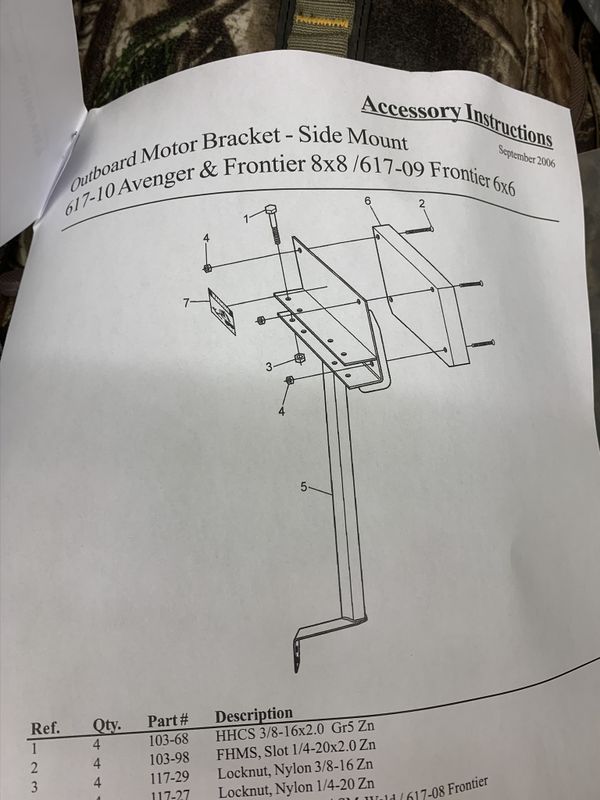

With maintenance complete it was on to the next project, installing an Argo accessory side mount outboard motor bracket.

This tidy unit installs easily by removing two trailer hitch bolts, putting the bracket in place and reinstalling the bolts. Next 4 holes are drilled into the body near the centre trim to lock the top in place using the included 4 bolts and lock nuts.

For a motor French chose a Yamaha 2.5 four stroke, long shaft outboard. This motor has an onboard fuel tank so no gas cans or hoses are necessary. Argos are not hydrodynamic so a larger motor wont necessarily make it go much faster. It will never go up on plane like a boat. Argo's will drive in water when you have Argo directional tires which French does, however it puts a lot of wear and tear on the machine as your only travelling 3-4km/h while the machine is operating at near full throttle.

This 2.5 propelled the machine faster than the tires, was quieter, burned much less fuel and prevented a lot of wear and tear on the Argo's engine, transmission and drive chains. Absolutely a win-win if you plan to do any amount of water travel.

Last on the list was switching all the tires back around from winter track configuration to summer mode. These wheels are offset to stick out more on one side providing necessary body clearance when running 18' wide tracks. In summer mode they tuck neatly under the machine with all tires facing one proper direction for water travel.

While changing wheels all outer wheel bearings were greased and excess wiped away for a full and proper service.

Lastly excess oil and grease were cleaned from the chassis and fluid film applied to prevent corrosion.

All loaded up and ready for our first Argo trouting adventure. Check out the May 28, 2020 trip on the Crew Adventures page!

Cheers, MIKE

Copyright © 2011 Michael Smith

|