|

Area51 Project - Bassan's Honda Foreman 400:

Machine Specs:

1996 Foreman TRX400FW 400cc Oil cooled single cylinder 5-Speed Manual Transmission

25x8x12 - Front Carlisle Black Rock tires

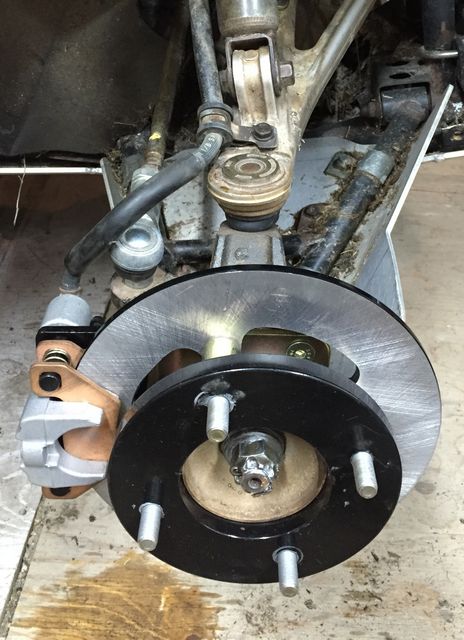

Super ATV Front Disc Brake

Conversion Steel Foot peg Extensions Tube Front & Rear Bumper 12" LED Light Bar Heat Demon Heated Grips & Thumb Warmer

Custom Steel

Front Bash Plate

A few years ago Bassan went shopping for a good reliable 4x4 ATV mostly to use Moose Hunting with the crew down in Trepassey. He came across this Foreman 400 in the spring of 2012 and negotiated a fair price knowing that it needed some repairs.

First was an inspection of the rear end, there was a bad rear left wheel bearing which usually leads to more trouble. That trouble is evidenced in the pics as muddy water gets past the seal next to the failed bearing and fills the axel tubes with crap. This causes corrosion leading to the splines of the axel and ring gear to wear out.

The rear drum brake wasn't in much better shape with well worn seals letting dirt and grime inside the housing.

Although not stripped yet, there were clear signs of wear so Bassan installed an aftermarket replacement axel, and replaced the left & right wheel bearings & seals using an All Balls Racing kit. The brakes were cleaned, new shoes installed and put back together with fresh seals. After the rear end was reassembled an aluminum skid plate kit from JnJ Industries arrived and installed in short order. This kit covers from the front differential to the rear of the engine, and included 2 A-arm guards for the front suspension.

The winch that came with the bike was a worn out Superwinch that had seen years of snow clearing by the previous owner. It wasn't working, the wiring was a mess and used a giant yellow controller strapped to the handlebars.

The other problem was that whoever installed the winch didn't install the upper bolts to fully secure the mount to the frame. The angle finder shows the angle of the bike frame, and just how badly the mount was bent over the years. A brand new Runva 2500lb winch and new mounting bracket was ordered online.

The Runva winch came with a tidy handlebar mounted micro switch so Andrea installed the contactor neatly in the rear storage compartment on the Foreman. The winch also comes with an auxiliary controller that can be plugged into the harness.

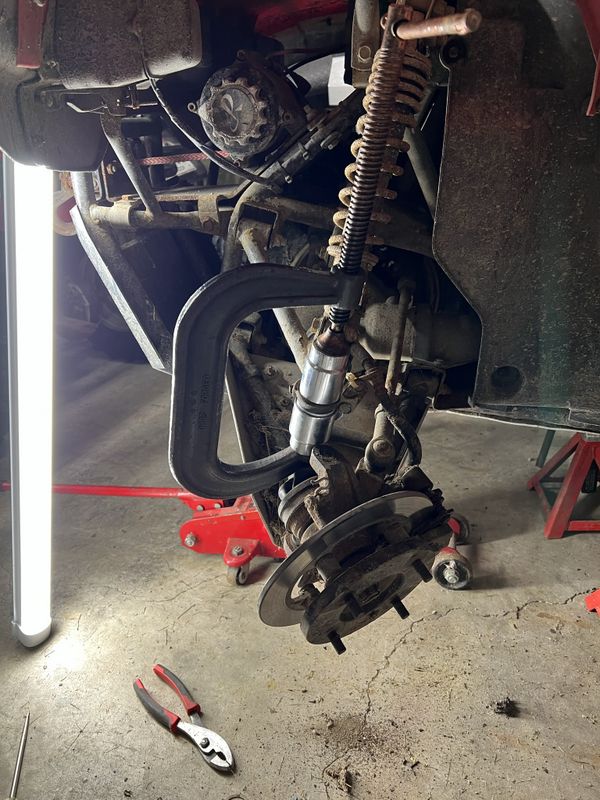

The stock front drum brakes had seen better days and were in need of a major overhaul. After adding up the cost for replacement parts, Andrea opted to order a Super ATV disc brake upgrade kit. These kits are very well made and relatively easy to install following the included directions.

The new brakes work much better than the old drum brakes and don't require nearly as much maintenance to keep them working well after even after months in the mud! While the front end was apart, two All Balls bearing & seal kits were installed in the front knuckles. The only other part that was replaced at this time was the cracked handle bar cover. Amazingly the dealer had a New Old Stock part in stock and sold it at a bargain!

in 2014 the Foreman needed a couple minor issues fixed. The starter was weak so Bassan ordered a rebuild kit online which included all wearable parts including new brushes. He rebuilt the starter and now its working very well. The voltage regulator also failed, a Honda replacement was quite expensive so he ordered an aftermarket part online.

The aftermarket voltage regulator didn't last through the following Moose Hunting trip later that year. On the second day it failed and boiled the battery completely dry. Luckily the bike finished the trip by using the recoil starter and made it home safely. A new proper Honda regulator was installed along with a new battery.

In 2015 we made a few more repairs/improvements to the ol' Foreman. The rear shocks were worn out giving a soft unsupported ride. Also the previous owner installed a homemade lift lift that was welded in place in the rear.

After much much research (and 1000 questions), Bassan ordered a pair of Bronco shocks online which turned out to be a great quality (and rebuildable) product that weren't overly expensive.

He also scoured a great deal on a Perfex long travel lift kit.

In this picture we had it on its highest setting, but the Bronco shocks are about an inch longer that the originals so we switched to the lower setting for a total lift of approximately 2 inches. The resulting ride was a huge improvement.

While we were working in the back we replaced the rusted out muffler heat shield with one I donated to the cause when I removed the stock muffler on my own Foreman project.

The last improvement piece we added this year was a set of foot peg extensions sourced on a local classifieds site. Bassan was sceptical about installing them at first, but after riding with them he said he'll never go without a set. They give a lot more support to stand on and provide great protection for your feet in uneven tangly terrain.

The last items tackled in 2015 were just general maintenance items such as changing the oil and adjusting the Intake & Exhaust valves. They were a little loose and the adjustment has made the bike much quieter and easier to start.

Although we've gotten out for a few rides, primarily this is a Moose Hunting machine and it does this job very well! Andrea made a custom box which not only secures a Kolpin Gun Boot, but allows him to carry our 1/2 moose at a time with ease.

2018 Update: In 2018 Bassan had a couple upgrades and repairs on his to do list for the trusty Foreman. First up was installing a set of Heat Demon heated hand grips and a thumb warmer on the throttle.

The new Heat Demon grips are a nice re-design over the older set I installed on my own Foreman in 2013, the new ones are much more comfortable and they tighten in place with an Allan head bolt as opposed to being glued in place with epoxy like my older set.

Bassan opted for the standard Hi-Low switch for the grips as opposed to the integrated 5 step controller that comes as a full kit. I made up a custom harness wrapped with Tessa Tape and terminated the wires to proper length for a clean tidy job.

Bassan's bike also did not have an 12v accessory plug so we installed a weather proof unit he ordered online, locating it in the upper left front fender. We wired the plug to the battery via a fuse & a relay so that the plug would only work with the key on. Then I wired the new heated grips into the new 12v accessory plug.

The two switches (one for grips & one for thumb warmer) were mounted in the handlebar cover on the Left Side. The single switch on the right side operates the engine oil cooler fan.

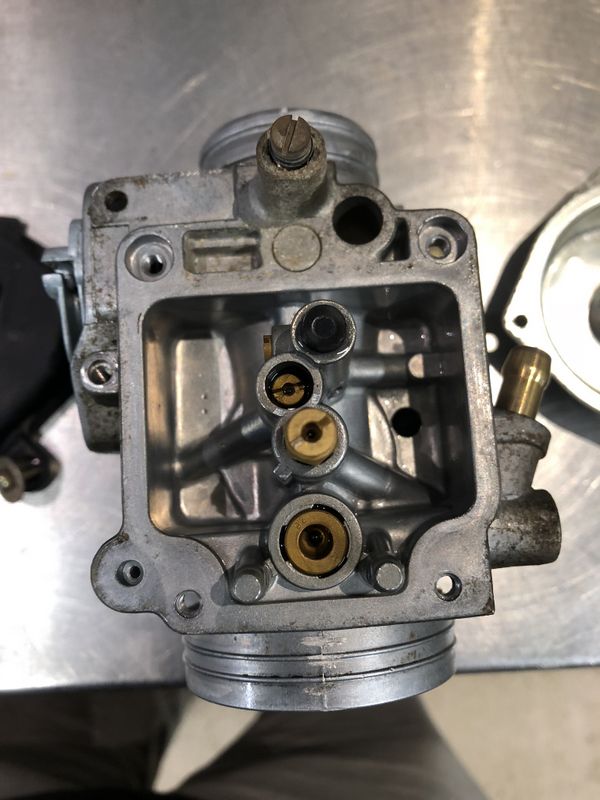

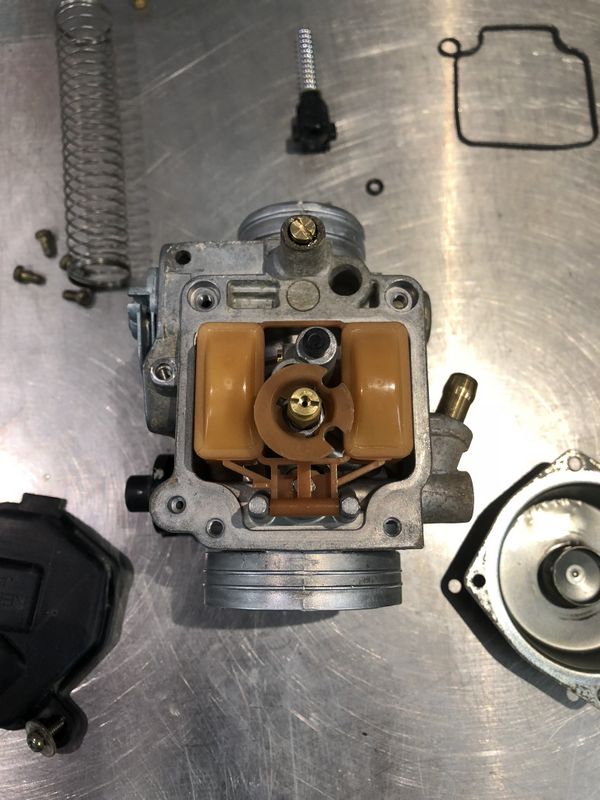

The final project for this year was a cleaning and rebuilding of the carburetor. Bassan removed and dropped the carb to my place so I could make use of my tools and parts washer. I always start by cleaning the mud & debris from the outside of the carb so I don't contaminate the delicate inner workings later.

Next the carb was disassembled to thoroughly clean and inspect all parts. Bassan ordered a full rebuild kit so I installed all of the included parts which consisted of new seals, jets, and needle. Some of the original jets were partially plugged up after years of use and old gas sitting in the carb.

Even this little bit of crap on the tip of the pilot jet can make a difference in how the bike starts and runs.

With the carb reassembled, Bassan reinstalled it on the bike, set up the idle speed and was happy to report that it starts much easier and runs very well! Now the trusty Foreman is all ready for the 2018 Trepassey Moose Hunting trip coming up in a few days time!

Submitted By: Andrea Bassan Cooling System Repair: The previous owner of my 96 Honda Foreman 400 had the cooling fan powered by a toggle switch and getting that back to factory had been on my list of to do items for the Foreman for some time now. The Foreman’s cooling fan is controlled by a fan control module and an oil temperature sensor. More often than not the fan control unit fails and a quick fix for a working cooling fan is to bypass the circuit by grounding the oil temperature sensor with a toggle switch.

Replacing the fan control unit is an easy and quick repair - unplug and remove old unit and plug in new unit located under the front fender near the steering post. However, instead of grounding the oil temperature sensor the previous owner had powered the fan directly from the battery. The wiring harness was hacked up a little and I wanted it fixed properly. Mike completed the wiring repairs by soldering in a new piece of wire and using some liquid electrical tape and heat shrink for a waterproof connection.

The previous owner also had cut the wire to the oil temperature sensor and instead of making a connector I went with a new OEM harness. It was less than $20 and well worth the cost for an easy reliable repair.

The oil temperature sensor is on the back of the motor, the first step is to drain the engine oil. Perfect timing as the bike also needed an oil change. Next I dropped the skid plate to get a wrench on the sensor and swapped the old one for a new one. The sensor may have been OK but since I was this far in I didn't want to get all the other work done to discover I also had a bad sensor.

I went with a synthetic blend oil over conventional oil and also used a Honda filter. A fresh spark plug completed the tune up.

Since I already had a fan bypass switch on the handlebar cover, I thought it would be a good idea to keep that in case I wanted to turn on the fan manually. Mike soldered installed a wire from ground, through the toggle switch, to the oil temperature sensor. Now when the switch is turned on it applies ground to the sensor circuit telling the module the engine is overheating, this will cause the module to command on the high temp light & cooling fan. I also replaced the oil temperature bulb as the previous owner removed it. A test ride confirmed the fan is working properly; the fan turns on automatically when the engine oil gets to temperature and also turns on with the fan bypass toggle switch. The oil temperature light does not come on unless the temperature gets very hot and under normal operation the light should not turn on.

In the process of completing this repair I also found a factory fused 12v power source that I did not know was there. Two of these wires can power an optional speedometer available for the '96 Foreman, while the other two wires provide a 15 Amp circuit for factory 12v accessories, a 12v outlet, or heated handle bar grips.

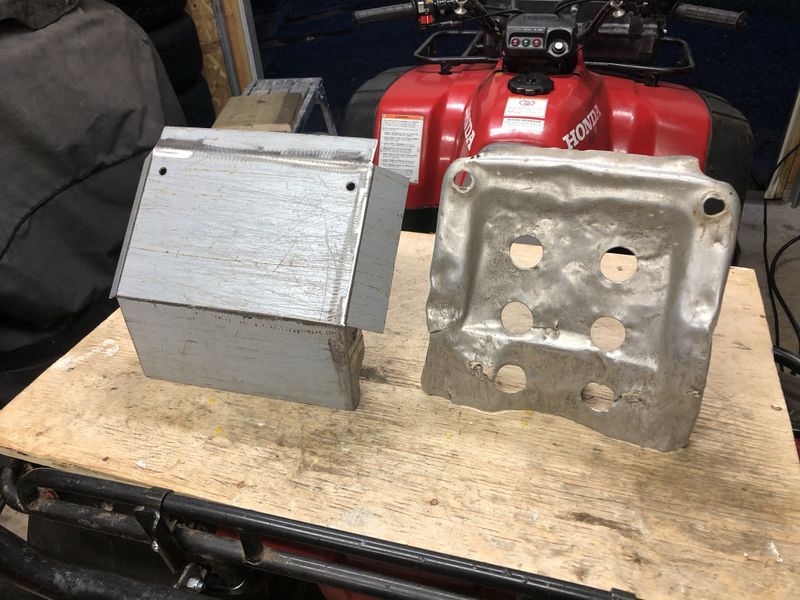

Front Bumper Replacement and Custom Skid Plate:

The front bumper on the Foreman had seen better days and was bent, cracked, repaired and welded in several places.

The OEM aluminum skid plate was also beaten up badly so I decided to replace both. I had removed the front plastics for the cooling fan repair, so replacing the bumper was easy. The lower part of the bumper attaches to the frame with 2 bolts that are thread into 2 welded nuts on the frame. These welded nuts broke loose so I ground down an old wrench to fit into the frame where the nuts are located. When reassembling, I used a nylon lock nut to prevent them from backing off.

I made a cardboard template to help design and fabricate the skid plate. When I was happy with the basic design, I transferred the measurements to a sheet of 1/8” steel plate.

To bend the steel plate I first made a relief cut with a zip disk and then widened the cut with a grinding disk. I then clamped the steel plate to something solid (my ATV trailer) and bent the plate to the required angle.

This method of bending the steel worked well. The key is to cut about 1/2 ways through and to bend slowly which should prevent splitting the steel plate along the cut lines.

After I was happy with the overall shape and fitment, Troy welded the relief cuts I made to bend the steel plate. This added structural strength that had been removed during the cutting and bending process.

A couple of coats of truck bed liner finished off the project and the skid plate was installed using the original hardware.

Bassan’s Foreman – Front Skid Plate 2022 Update: The front of my Foreman didn’t have a good anchor point for winching (with a snatch block) or attaching tie down straps when trailering the bike. No matter where I attached the tie down strap to the Foreman, I always seemed to catch a sharp edge that ripped through the strap. The custom skid plate that I installed last year is made from 1/8” steel plate and is plenty strong for an anchor point. The update was simple. A T-shaped tow hook would be made from 1/4” steel flat bar. A slit would be cut in the bumper for the short leg of the T to come through and welded to the back side of the bumper would provide added strength. The short leg would be drilled to accept a 1/2” shackle or a hook from a tie down strap.

With the design complete, Troy Coldwell was tasked to put his welding skills to work.

Troy suggested a couple of design changes to provide extra strength. The long part of the T was cut into 2 pieces. This would provide a larger welding surface for the short leg that extended through the plate. A gusset was also added to the short leg to prevent it from twisting.

I haven’t used the tow hook as a winch anchor point yet but it works great as an anchor point for tie down straps. The tow hook is low enough on the frame that it’s not necessary to compress the suspension to prevent the bike from bouncing around on the trailer when trailering, and no more broken tie down straps!

Moose Hunt September 2022

November 2022 Glenwood Trip

2023 Quick Update:

Moose Hunting September 2023

In October Bassan was having some troubles with the brakes on his Honda Foreman 400. We took it apart and found the pads separated from the backing plates. New parts were purchased and installed along with a quick maintenance.

Yup.

Lastly a new left side upper ball joint was installed to replace the sloppy worn out old part.

Cheers, BASSAN

Copyright © 2011 Michael Smith

|