| How To: Rebuild

a Honda Snowblower Crawler Gearbox

In 2017 my Honda HS928 Snowblower had been through 11 Newfoundland winters, and racked up a heck of a lot of hours. I never clean just my own driveway, I love to help neighbors especially after a major storm so my blower has quite a few hours on the clock. A well known problem with these units is for the track drive Final Gearbox to fail leaving the machine motionless. The drive system consists of a Hydrostatic Oil Pump which is controlled by the lever on the control panel. Power is fed to the tracks through a gear case which is grease filled and not sealed 100%.

There is a grease fitting behind the right side track that isn't listed in any service literature for these machines. Greasing this fitting regularly can help extend the life of these gear cases which usually fail at the bottom bearing for the drive axel. Most people make this repair after the blower breaks and stops moving. I inspect my machine regularly and noticed that there was a lot of free play in the tracks. I could move the machine forward & back 6" by pushing/pulling. Next way to check is by lifting the Snowblower up and checking for driveshaft play where the crawler drive shaft exits the gear case on the right side. Any free play here is a sign of a failed lower bearing.

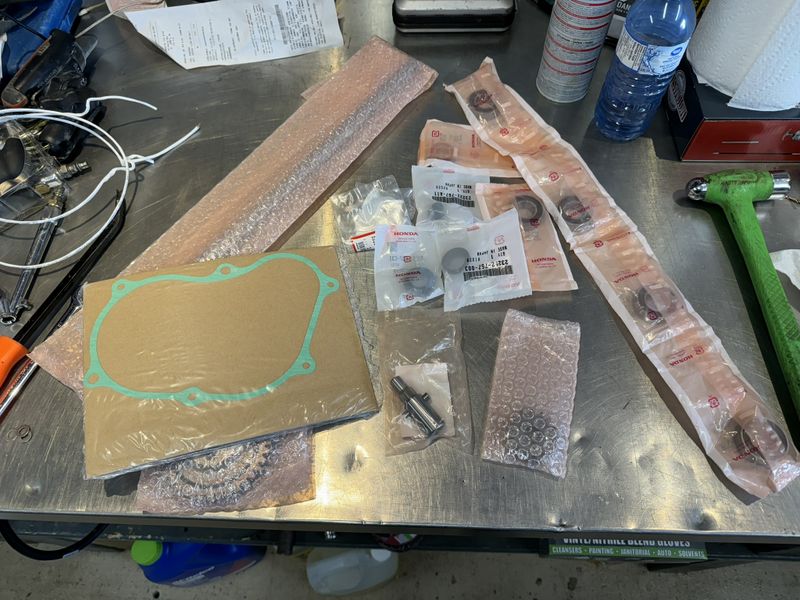

Fortunately the good folks at my local dealer Honda One in Mount Pearl, NL put together a complete kit for properly performing this repair.

The kit includes all the parts known to fail in this gearbox. The kit includes some gears (the rest are know not to fail), new drive axle, all bearings, bushings & seals inside the case, and bearings for the drive axle support bracket on the Left Side and bearings for both track support brackets. If you take on this job, don't cheat and replace only visibly worn parts, install the complete kit to maintain reliability of the machine.

I begin disassembly by turning off the fuel switch, draining half of the fuel from the tank and all of the fuel from the carburetor, then stand the machine up on the bucket and securing the handles of the unit to an anchor point in the shop with a strap. I always keep my machine doused in Fluid Film so everything was in great shape and rust free, many customer machines I've fixed are good and rusty, which makes them harder/more expensive to work on as parts are seized.

I remove both tracks & the 4 wheels by loosening the adjusters and pulling the outer pins. Take pictures of all the spacers and washers behind the wheels for a reference during reassembly.

Here's a quick pic in case you forgot! There is another Spacer and Pin with one flat side behind this track support bracket.

Keep your parts neatly organized! Next I pulled the top pin for the height adjuster piston, further loosened the track adjuster bolts, removed left & right crawler frames and rear axel. Next I swing the rear crawler frame and the height adjuster piston up and out of the way securing it to the handle bars with a tie strap.

The outside cover of the gearbox is also the Right Side plate of the Snowblower frame (black). Remove the rear & bottom skid plates, then remove all the 12mm bolts holding the side plate to the bucket & engine mount plate (there is one on top which necessitates removing the Headlight Bracket and plastic Belt Cover), two nuts for the belt tensioner pulley bracket, and finally all the 10mm bolts that attach the side plate to the gearbox. Although you don't need a wrench for the inner nuts, these are nuts and bolts so be careful not to loose the nuts. Note two of the 10mm bolts are different than the rest as they have collars for aligning the cover & case during re-assembly.

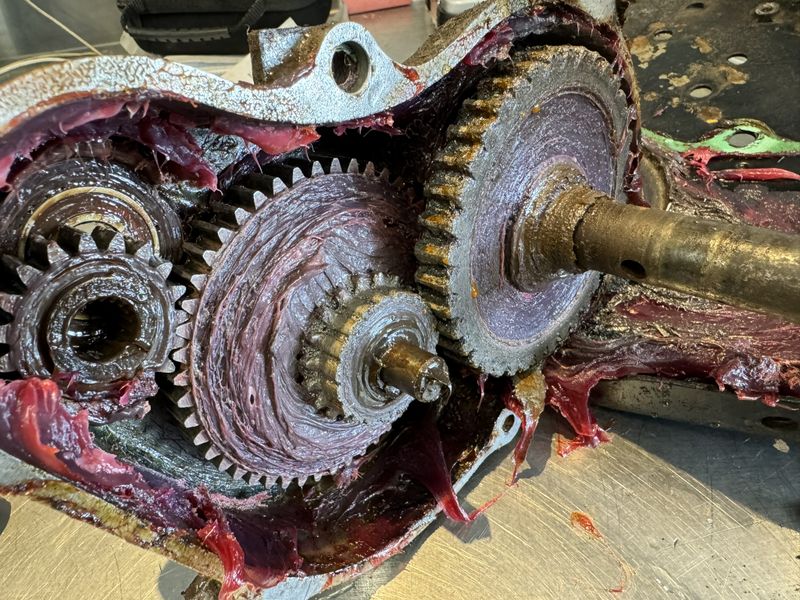

The inside of most transmissions are extremely dirty, sometimes wet, often rusty. Many I've worked on that haven't been maintained over the years have very little grease inside, I always added more to mine but since they are pretty well empty from factory it probably wasn't enough.

One particularly bad gear set found during just such a rebuild on a 7/24 in February 2024.

The repair kit from my local dealer, Honda One, includes a new crawler drive axel, the big lower gear, the smaller of the two middle gears, the shaft that both middle gears run on, all new bearings, new plastic bushings, seals, and a paper gasket. Their parts kit also includes the bearing for the crawler driveshaft where it goes through the left side frame, and two crawler chassis bearings behind the white drive cog wheels. For those who don't have a kit available I'll post the Honda part numbers at the bottom of this article.

Don't forget to disconnect the tension springs for the belt tensioner pulleys as they attach to a bracket bolted to the back side of the gear case. To remove the gearbox it should now just slide off the crawler drive axel and the hydrostatic pump input shaft up top. However, on many machines bearings are seized to the crawler drive axel so often I cut the axel in two pieces between the gear case and left side frame to facilitate removal. .

Taking pics of the spacers, shims and washers will make reassembly a lot easier, it's usually a better idea to Google Search & print off the exploded parts diagram & parts description online.

The indentation in the crawler drive axel pictured above is were a large pin normally resides. When the bottom bearing fails the shaft wobbles, then the large bottom gear cocks over and snaps off the pin causing the blower to stop moving.

Gearbox removed, the hydrostatic pump remains in place as its in great shape and not leaking.

The bearings can be a PITA to remove because they are often rusted and seized in place. The top and bottom bearings can be hammered out from the back side of the gear case using a steel punch against the inside race. On my blower the lower bearing came out in pieces leaving the bearing race stuck inside the gear case. I had to very carefully cut a groove using a metal cutting wheel in my Dremmel Tool all the way through the steel race but not into the aluminum gear case, then I used a small flat chisel and hammer to loosen and eventually split the race.

The middle bearing can be difficult as it sits in a pocket with no access from the back side. On my machine the centre post sized to the bearing so I drilled a single 3/16" hole and hammered it out with a round punch, luckily the shaft and bearing came out at together. In the past I've drilled two small holes right behind the outer bearing race for the centre bearing and popped it out using a small round punch. Before reassembly fill any drilled holes with silicone automotive gasket maker.

Since then I purchased a Blind Hole bearing puller & slide hammer which makes the job much easier. You choose the right size puller, place it inside the bearing all the way. Use two wrenches to expand the jaws so they grasp the inner side of the bearing.

Next I place the transmission case on the floor with a rag, stand on it and operate the slide hammer to pop out the bearing without damaging the case.

The case and all reused parts were thoroughly cleaned in a parts washer.

Installing new Bearings.

In the top of this pic you can see where the track drive gear was rubbing the aluminum case due to the failed bearing. Many people let this go for so long that the gear wears clean through the aluminum housing meaning it would also have to be replaced. Catching this repair early can save you money!

Next new bearings were installed in both crawler drive frames, and a new bearing to support the crawler drive axel on the left side chassis.

To reassemble the machine first slide the crawler drive gear box over the input shaft from the hydrostatic pump. next slide the washer and spacer over the crawler drive axel and then slide it in through the transmission case then on thought the left side frame bearing. Spacer and washer pictured above.

Next install the middle shaft, spacer washers and gears, then the bottom gear and lastly the top gear. This is where the explode diagram is handy to get the location of spacers/washers correct. As I reassemble I always use lots of grease making sure everything is coated and voids filled. This can often use up most of a tub or tube of grease. My current grease of choice is Lucas Red-n-Tacky or Lucas Green Heavy Duty. My mindset is that if the gear case is full, when I add grease from my grease gun through the nipple on the centre shaft, new grease should be pushed down protecting the lower bearing.

Don't forget to install the new paper gasket on the gear case, a little grease will hold it in place. Next install the 3 replacement bushings into the outer (black) cover before installing it on the machine. Install and snug the two 10mm bolts with an alignment collars first to align the cover to the gear case. Next install the rest of the 10mm bolts, wrestle with the bracket for the belt tensioner pulleys, then install the 12mm bolts that hold the side cover to the frame. I barely snug bolts as I go and fully torque them after they are all in installed.

With all remaining bolts reinstalled, and return springs for the belt tensioners reattached to the gear case bracket, install the new drive axel seal which goes over the drive axel onto the side plate behind the right side cogged wheel. The rest of the machine was reassembled in reverse order.

The old parts are usually in pretty hard shape, the kit from Honda One is perfect and economical in that it replaces everything you need while retaining a couple of the gears that are OK.

Don't forget on future services that there is a grease nipple on the crawler drive gearbox cover behind the right side track that will allow you to add grease to the gear box. I got my machine back together just as the first Blizzard of the 2017-2018 Winter season arrived!

Cheers, Mike Copyright © 2011 Michael Smith

|